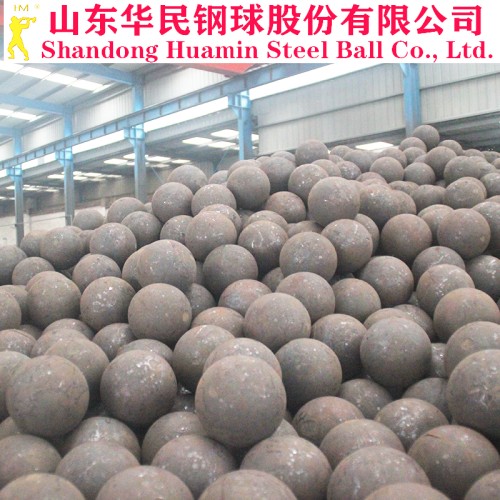

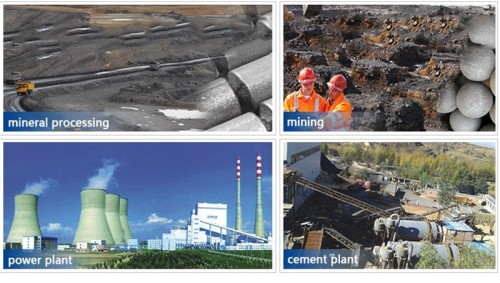

Huamin steel balls company is a certified ISO 9001Company, specializes in the design, development, production, and servicing of high chromium wear resistant materials for grinding equipment in cement, mining and quarry industries.

High chromium white cast iron grinding ball is also known as high chromium alloy casting ball and high chromium steel ball, referred to as high chromium ball. Nowadays, most domestic wear-resistant material enterprises are mainly based on medium-frequency electric furnaces, and smelt high-quality scrap steel and chromium alloy materials after reasonable matching. Microalloying and tempering of hot metal; And add a unique metal mold and sand die casting molding process; Then it is quenched and tempered at high temperature to obtain a martensitic matrix to achieve higher hardness and wear resistance.

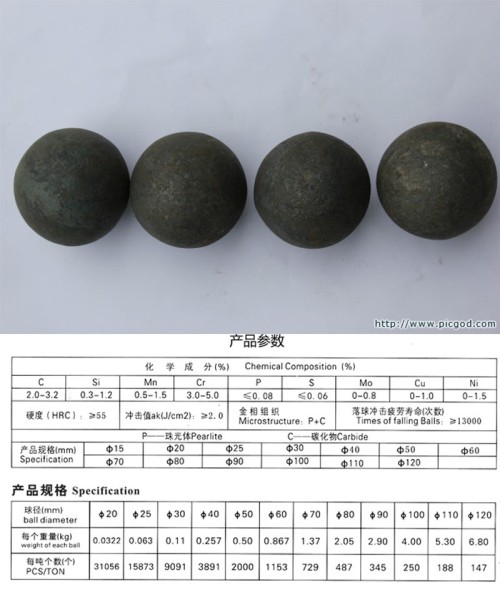

In terms of chemical composition, there are dozens of different materials from low chromium to high chromium, which can be described as a wide variety of materials.

In order to standardize the industry standard, let everyone have a clear understanding of the chromium alloy casting ball, casting ball GB/T17445-2009 industry standard stipulates that the chromium content of low chromium ball is 1%-3%, and the hardness HRC≥45;

Chromium content of 4%-6% in a variety of alloy balls, hardness HRC≥47;

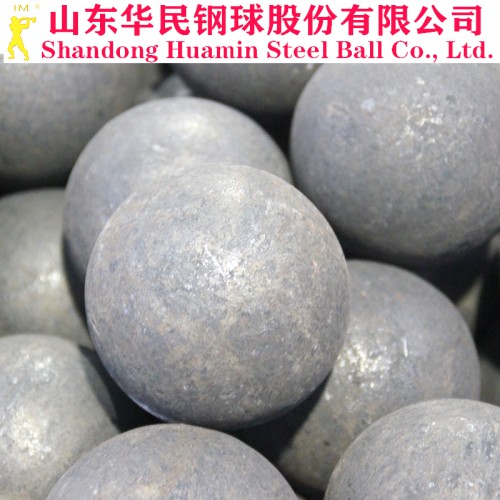

Medium chromium alloy ball chromium content is 7%-10%, hardness HRC≥48; High chromium alloy ball chromium content ≥10%-14%, hardness HRC≥58;

Special high chromium ball chromium content of more than 14%, hardness HRC≥58.

Packing and delivery

Bag, 1 ton/bag

Iron drum packing, 900KG/ drum.

Land delivery, 30 tons/truck

Ocean delivery, 27 tons /20 feet container

Our products are widely used.

We have an advanced after-sales service team to provide you with thoughtful and accurate service.·

If you have other questions and inquiries, please feel free to contact us.

通过

通过