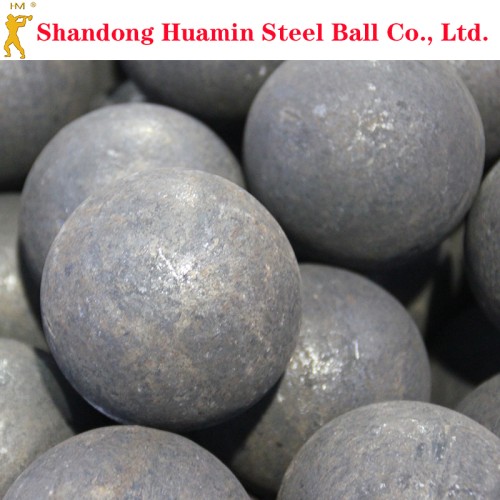

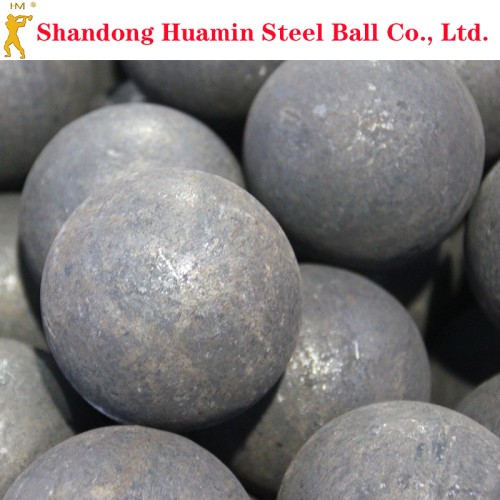

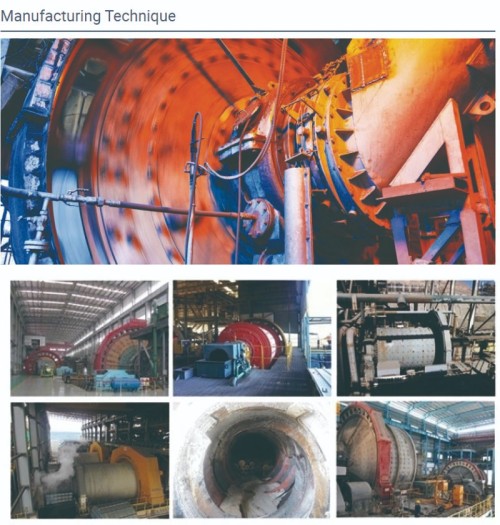

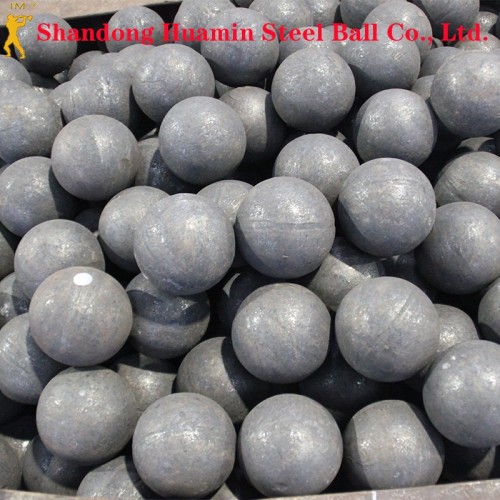

Grinding balls for steel grinding machines (referred to as wear-resistant steel balls) are a type of crushing medium used in ball mills to crush materials within the mill. After 38 years of research and development and innovation, our company has conducted in-depth studies and combined the actual working conditions of ball mills. Through the research and improvement of steel ball materials and the corresponding heat treatment process, we have developed special wear-resistant balls for ball mills with higher volume hardness and better wear resistance.

This ensures the grinding effect while effectively improving the grinding efficiency, which is conducive to energy conservation and consumption reduction in mines. The annual production capacity of our products is 200,000 tons. Wear-resistant balls are mainly used in metallurgical mines. The products are sold far to major domestic mines and regions such as Africa, America and Southeast Asia.

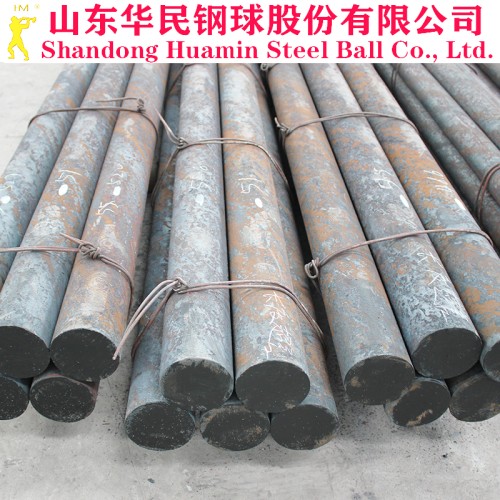

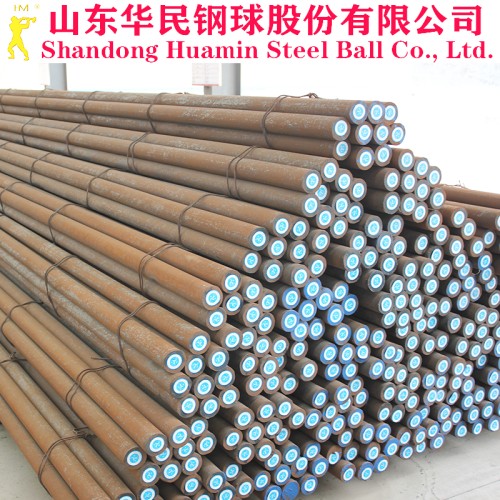

We select high-quality round steel as raw materials, adopt advanced equipment, unique heat treatment processes and strict quality control systems, which enables our forged steel balls to have better overall hardness performance. The surface hardness can reach 58-65HRC and the volume hardness can reach 56-64HRC.

The hardness distribution is uniform, the impact toughness value is 12J/cm ², and the breakage rate is much less than 1%. Chemical composition of forged steel balls: Carbon content is 0.4-0.85, manganese content is 0.5-1.2, and chromium content is 0.05-1-2.

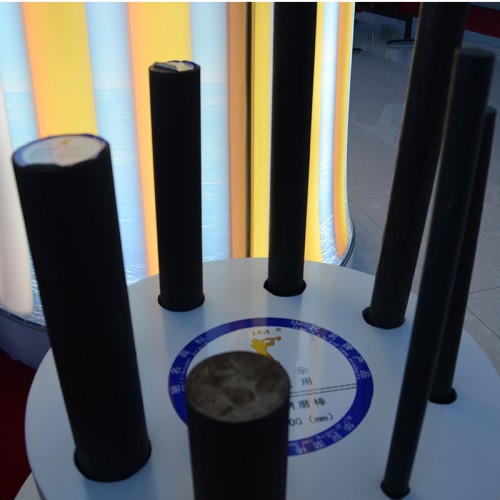

We can produce different sizes according to the requirements of customers.

Forged steel balls are mainly used in various industries such as mines, cement plants, power stations and chemical plants. To ensure the excellent performance of grinding balls, we have established a complete quality inspection system and advanced quality control and inspection equipment.

We have a complete logistics channel and can deliver grinding balls by land transportation, rail transportation, sea transportation, etc.

通过

通过